Resin 3D printing

Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), is a popular 3D printing technology that uses liquid photopolymer resin to create three-dimensional objects. Unlike plastic filament-based 3D printing, resin 3D printing uses a liquid resin that solidifies when exposed to a specific light source, typically ultraviolet (UV) light.

Here’s a general overview of how resin 3D printing works:

1. Designing the Object: Like other 3D printing methods, the process begins with creating a digital 3D model of the object using CAD software. The model can also be obtained from existing 3D designs or scanned using 3D scanners.

2. Slicing: Similar to plastic 3D printing, the 3D model is sliced into thin horizontal layers using slicing software. Each layer represents a cross-section of the object and determines the movement of the 3D printer.

3. Preparing the Printer: The resin 3D printer consists of a build platform and a vat filled with liquid resin. The build platform is typically attached to a vertical axis that can move up and down. The vat contains the liquid resin and has a transparent bottom that allows UV light to pass through.

4. Printing Process: The resin 3D printer starts the printing process by dipping the build platform into the vat, just below the surface of the liquid resin. The UV light source located underneath the transparent bottom of the vat then exposes the first layer of the object according to the sliced model. The UV light causes the exposed resin to solidify.

5. Layer-by-Layer Building: After the first layer is solidified, the build platform moves up slightly, and the process repeats for the next layer. The printer continues this layer-by-layer building process until the entire object is printed. The build platform gradually rises out of the liquid resin as each layer is cured.

6. Post-Processing: Once the printing is complete, the object is typically rinsed in a solvent to remove any excess, uncured resin. The object may require additional curing under UV light to fully harden the resin. Support structures, which help in the printing process, may also need to be removed and any necessary post-processing, such as sanding or painting, can be performed.

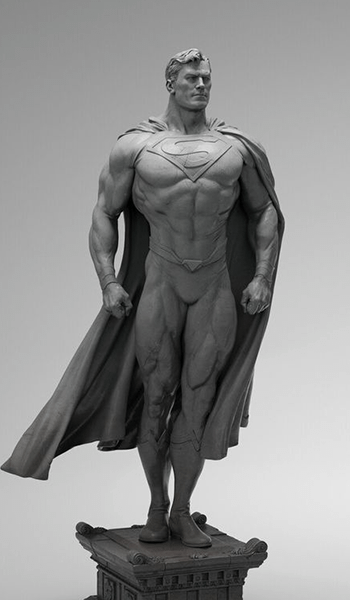

Resin 3D printing offers high-resolution prints with smooth surface finishes, making it suitable for detailed and intricate objects. It is commonly used in industries such as jewelry, dentistry, prototyping, and small-scale production. However, it’s important to note that resin printing can involve handling toxic or sensitive materials, so appropriate safety measures and proper disposal of waste materials are essential.

Contact us

E :printforged@gmail.com T : +91-83768 42992

IF YOU HAVE QUESTIONS PLEASE

CONTACT US

Fill fields and find approximate your repair